As power technology continues to evolve, power safety issues are receiving increasing attention. In particular, temperature monitoring of electrical equipment enables more direct assessment of whether the equipment is operating normally. This has given rise to wireless temperature measurement technology.

Wireless temperature measurement technology is a monitoring solution that does not require wiring and transmits temperature data through wireless communication. It is suitable for high-voltage, enclosed, mobile, or multi-point dispersed scenarios. The core process involves sensor data collection → wireless transmission → reception and processing → platform monitoring, enabling real-time monitoring and anomaly alerts.

- Core components:

- Wireless temperature sensor: temperature sensing element + microcontroller + wireless module + power supply (battery/CT induction), mounted or embedded at the point being measured, with a unique ID.

- Receiving Gateway: Receives sensor data, collects the data into a collector, and then uploads it to the platform.

- Monitoring Platform: Data storage, real-time display, threshold alerting.

- Application scenarios:

- Power: Switchgear contacts, cable connectors, transformer windings to prevent overheating and shutdown.

- Industry: Motor bearings, kilns, pipelines, chemical reactor vessels to ensure the stability of equipment and processes.

- Architecture: Distribution rooms, data centers, cold chain storage facilities, fire protection, and energy efficiency optimization.

For the purpose of electrical safety testing, Acrel’s wireless temperature measurement module offers a safe and reliable solution.

▲ Installation and contact issues:

The temperature measurement probe must be fully in contact with the object being measured. If the surface of the object being measured is rough, or if the installation location is constrained by space limitations (such as within an electrical switchgear), poor contact can directly affect the accuracy of temperature measurement.

▲ Measuring temperature is difficult.

Due to the fact that many devices requiring inspection are located within electrical cabinets, measuring temperatures is difficult, and the risk of electric shock for the measurement personnel is significant.

▲ High costs, low returns.

Traditional temperature measurement solutions are characterized by high costs, low returns, and significant labor input. Regular inspections, battery replacements, and fault localization require professional personnel to be present on site. The labor costs incurred far outweigh the costs of the equipment itself.

For the purpose of electrical safety testing, Acrel’s wireless temperature measurement module offers a safe and reliable solution.

Key parameters

· Power source: AC/DC100-265V;DC12-48V

· Temperature points: 240 points;1440 points

· Wireless distance: Receiving sensor 150m (in open area);Receiving repeater 1km (in open area)/Receiving sensor 150m (in open area);Realy distance 1km (in open area)/Receiving sensor 1km (in open area)

· Precision: ±1℃

· Range of: -50℃~+125℃/-40℃~+140℃

Key wireless temperature measurement devices.

1. ATE100 –Battery-type sensor

ATE200 – CT power-harvesting sensor

2. ATC600 – 240 points

ARTM-Pn – 1140 points

This device is highly popular in many countries, offering fast and efficient unmanned inspections that provide effective protection for electrical safety

Field application diagram.

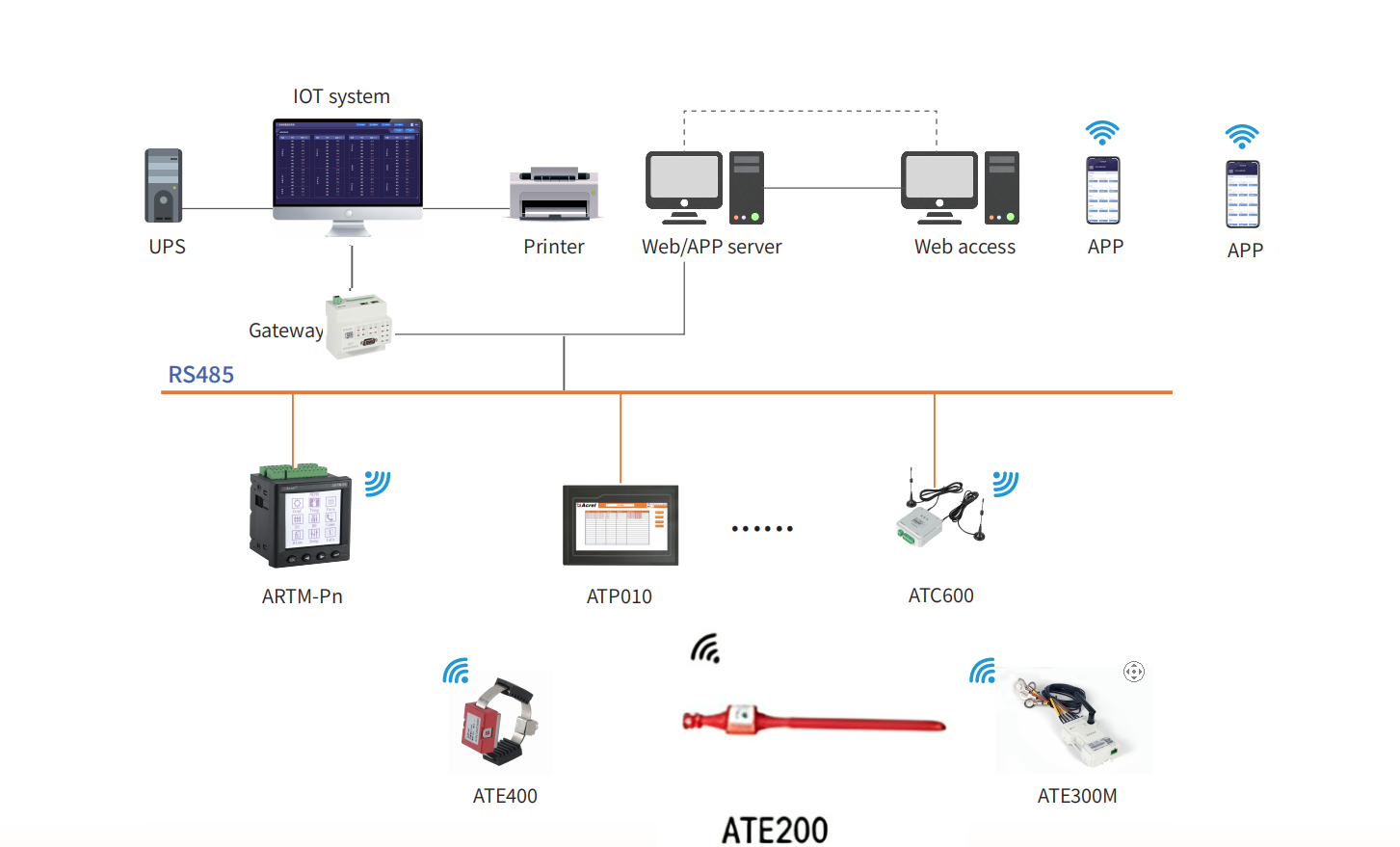

This image pertains to the ATE200 wireless temperature measurement and data collection system, which enables real-time monitoring of equipment temperatures. If an abnormal temperature is detected, an alarm can be triggered.

Application scenarios

This image illustrates the application scenarios of the ATE200 wireless temperature measurement system, which enables the monitoring of high-voltage contactor temperatures, capacitor temperatures, temperatures of the front ends of high- and low-voltage busbars, reactor temperatures, temperatures of low-voltage cable connectors, transformer temperatures, and motor temperatures, among other things.

Post time: Jan-12-2026