Demand monitoring and management is a critical yet often overlooked aspect of modern energy systems—especially for industrial and commercial consumers aiming to optimize electricity costs and ensure grid reliability. This article breaks down what demand is, why monitoring it matters, and how tailored solutions are being deployed in markets such as Malaysia.

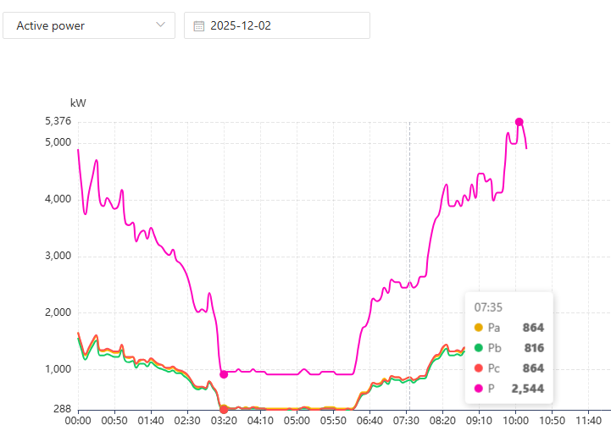

In electrical systems, demand refers to the average rate of electricity consumption over a specified interval, typically measured in kilowatts (kW) or megawatts (MW). It reflects how much power a facility draws from the grid at any given time.

Key terms include:

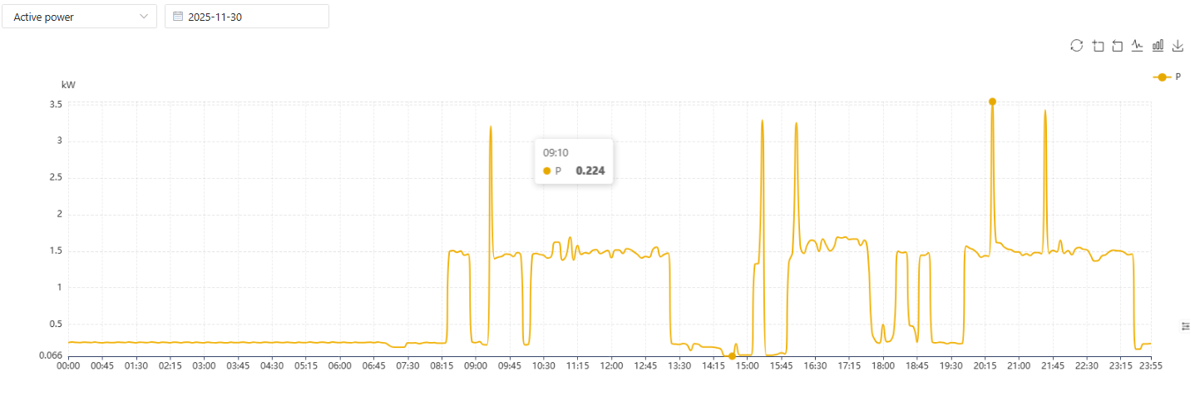

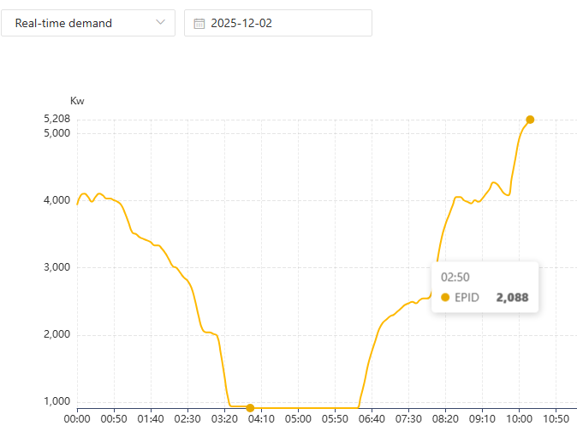

Demand Interval: Usually 15 minutes, though it can vary by region (e.g., 30 minutes in Malaysia).

Sliding Window (or Slip Time): Often set at 1 minute, meaning demand is recalculated every minute based on the preceding interval.

Maximum Demand: The highest average demand recorded over a billing period (e.g., one month). This peak value is crucial for utility billing and infrastructure planning.

Demand is not the same as energy consumption (kWh). Instead, it represents the intensity of electricity use at a point in time.

Monitoring demand serves two primary purposes:

▲Prevent Overloading & Ensure Safety

Electrical infrastructure—transformers, cables, switchgear—has defined capacity limits. Continuous demand exceeding these limits can lead to overheating, equipment damage, or even failure. Real-time demand monitoring helps facilities stay within safe operational thresholds.

▲Reduce Electricity Costs

In many tariff structures, electricity bills consist of:

- · Energy Charge: Based on total kWh consumed.

- · Demand Charge: A fixed fee based on the maximum demand recorded during the billing period.

By managing and flattening demand peaks, businesses can significantly lower their demand charges, which often make up a substantial portion of commercial and industrial electricity bills.

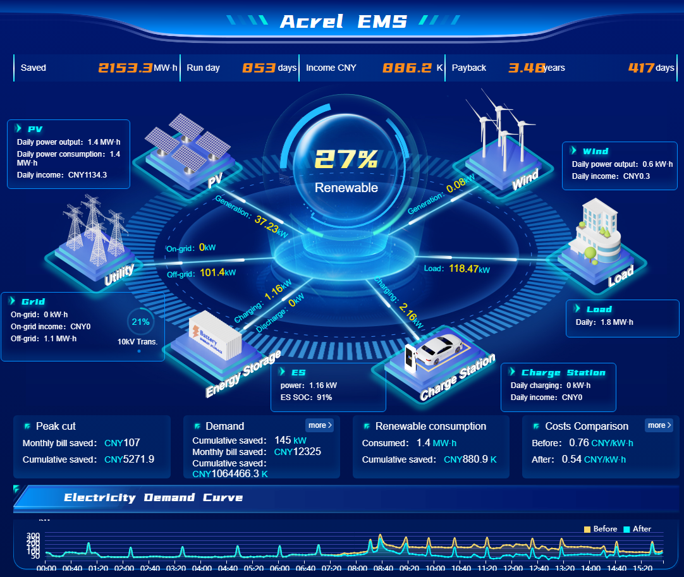

Effective demand management involves:

- · Shifting non-essential loads to off-peak periods.

- · Using energy storage or onsite generation during high-demand windows.

- · Implementing automated load-shedding controls.

Different regions have unique demand calculation rules. In Malaysia, regulations specify:

Demand interval: 30 minutes

Sliding window: 1 minute

Weekly time-of-use rates, with separate tariffs for peak and off-peak periods

Demand charges apply only to usage during peak periods

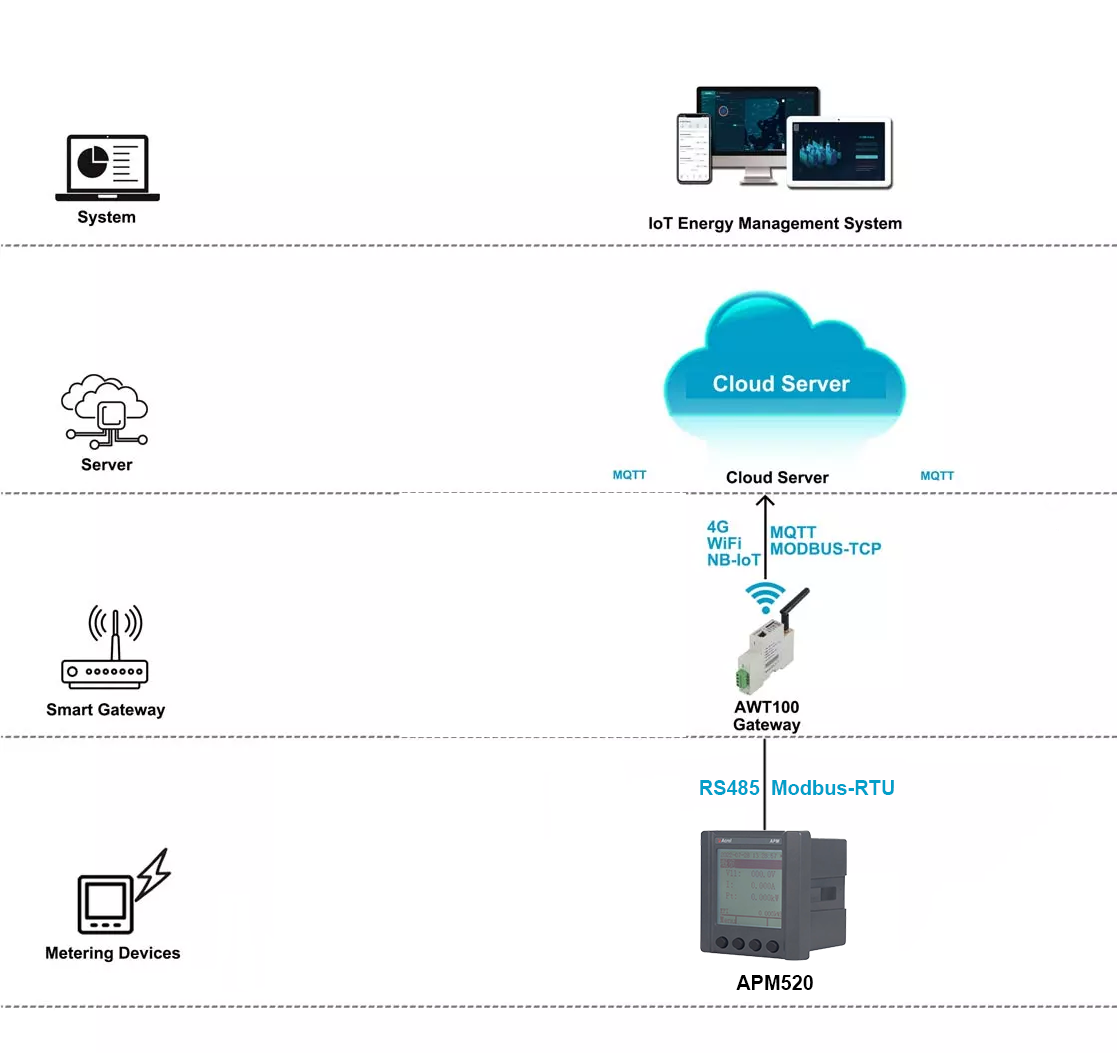

To meet these requirements, specialized solutions such as the APM520 energy meter (with custom firmware) have been deployed. This system:

1. Calculates demand separately for peak and off-peak intervals.

2. Integrates with gateways and cloud platforms (e.g., AWT + EIoT) to visualize real-time demand trends, track maximum demand, and log occurrence times.

3. Enables facilities to actively manage loads and avoid peak-based demand penalties.

APM 5xx

1. Maximum demand measuring

2. 4*DI + 2*DO

3. MAX input: 3*400/690V

AWT100

1. Uplink communication: 4G / Wifi / Ethernet / Lora

2. Downlink communication: RS485 & Modbus-RTU

3. Upstream Protocol: MODBUS-TCP, MQTT

IoT platform

1. Reduce energy costs

2. Slash carbon footprint

3. Achieve sustainability targets

Post time: Dec-08-2025